More 1000℃ Severe Working Conditions,

Around 100 ton/day Coal Used for 200 thousand brick production,

Electricity Highly Used(10 times more compared to HBM),

More 20% Defective Products, 24hours 365days Work

Around 100 ton/day Coal Used for 200 thousand brick production,

Electricity Highly Used(10 times more compared to HBM),

More 20% Defective Products, 24hours 365days Work

For 100 thousand bricks per Day, Coal 50 ton, Charcoal 20 ton used

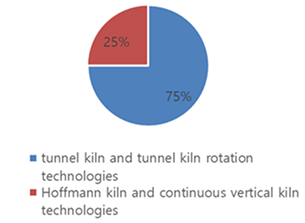

(Tunnel or Rotation Tunnel Type)

Each Brick used 0.5kg coal à 2 times compared to Bangladesh

(Due to Soil and Coal mixed together for shaping brick)

(Tunnel or Rotation Tunnel Type)

Each Brick used 0.5kg coal à 2 times compared to Bangladesh

(Due to Soil and Coal mixed together for shaping brick)